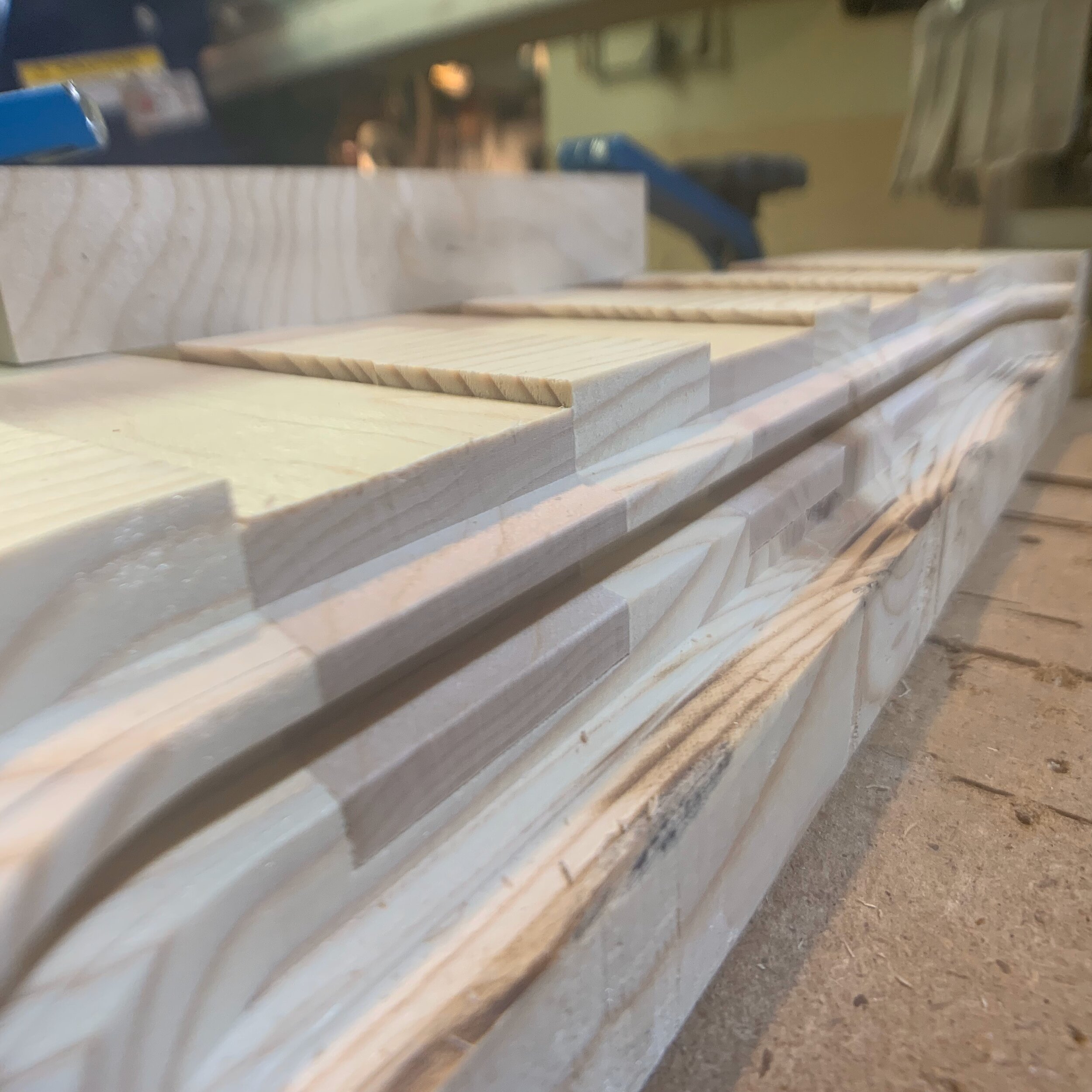

Glue Joint

Router Cut Glue Joint

Using a router bit with a glue joint profile increases the surface area of the two mating pieces of material that are going to be glued together. The mechanical fit in addition to increased surface area makes the glue joint the strongest point of the two pieces of material. In addition to these pragmatic features, the interlocking fingers of the joint produce an attractive detail element. The bit used here is the Amana Tool 55388 Carbide Tipped Glue Joint Bit. Many bits making this type of cut come in a set of two: one for each mating cut. This bit makes the cuts for both mating pieces - one piece is cut with the bottom side up and the other with the bottom side down. This bit works great in a router table with the fence guiding the cut, or in a CNC machine as we’re showing here. An advantage of the CNC machine is that with the precision of the z zeroing routine, the bit can set so the center of the bit is exactly in the center of the piece to be cut. Because the profiles fit together in the opposite orientation, any offset error (up or down) is amplified times two when the parts are glued together (patience and precision in setup pays off!) In this cutting setup, we are cutting slow, taking conservative passes to ensure clean cuts. This with the additional zero clearance pocket jigs ensure that the cuts are extremely clean and there is no tear-out. Care in all of these steps is rewarded with the tight fit and very minimal sanding that is necessary after gluing.