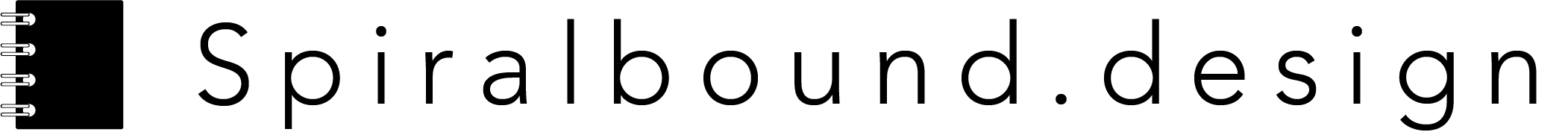

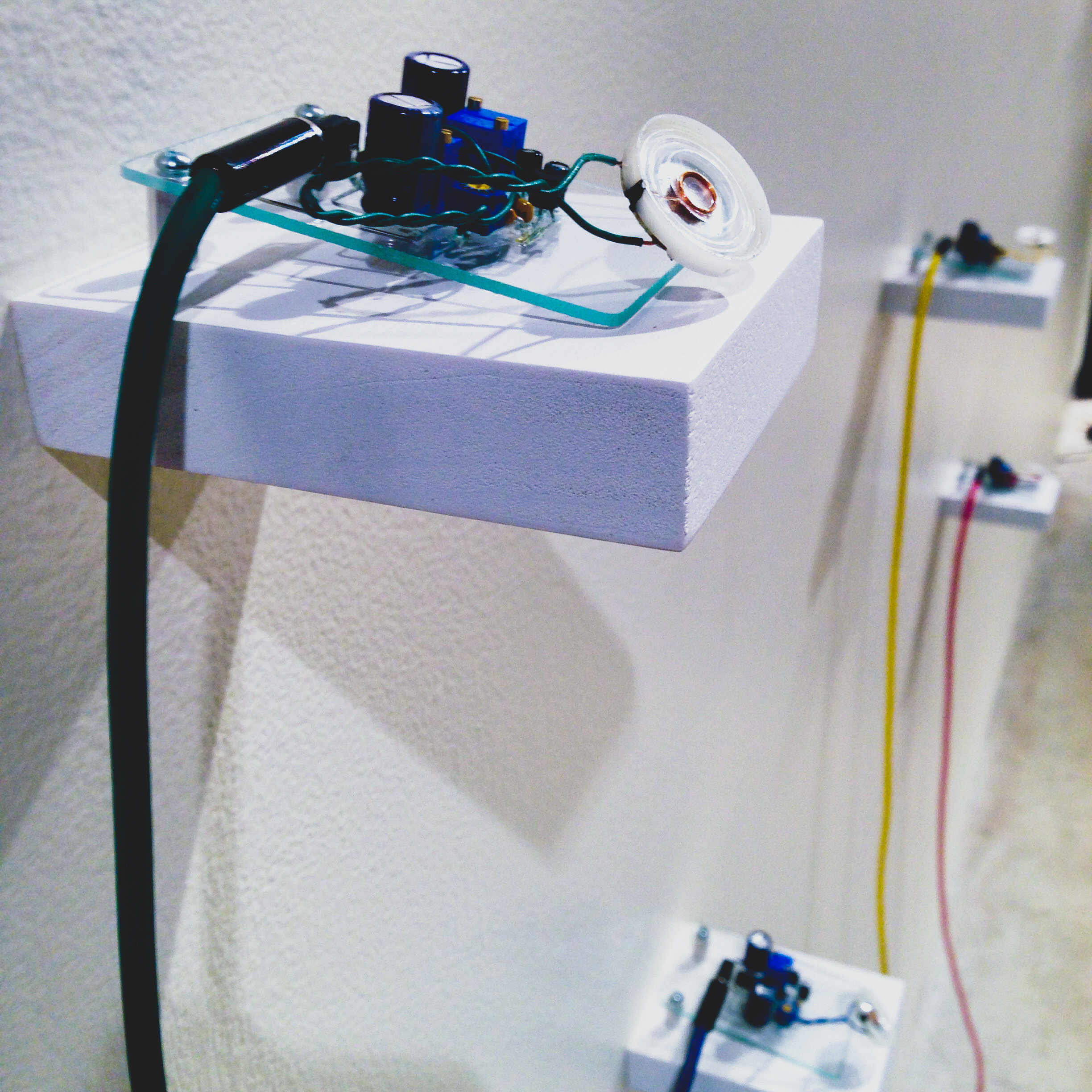

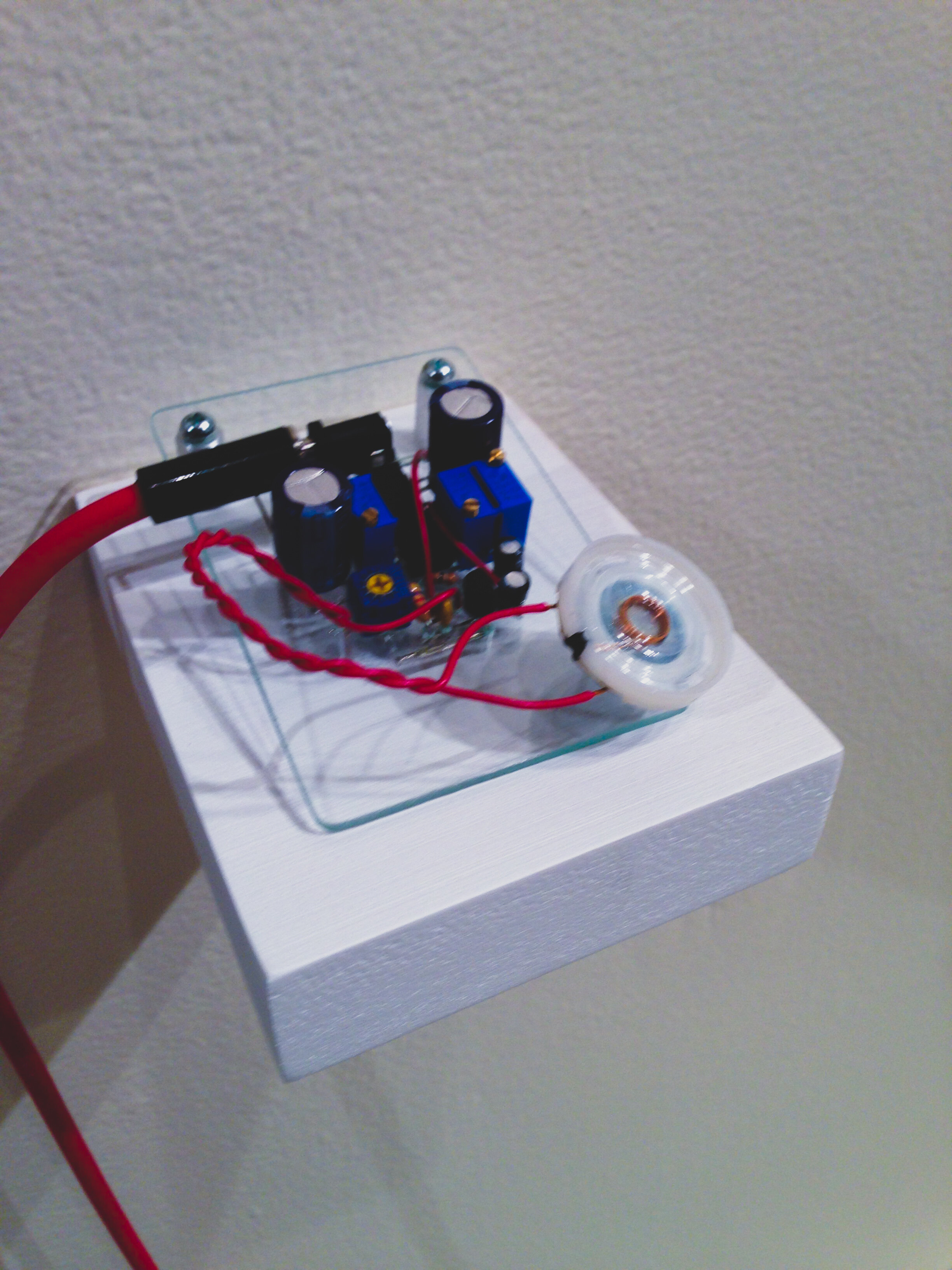

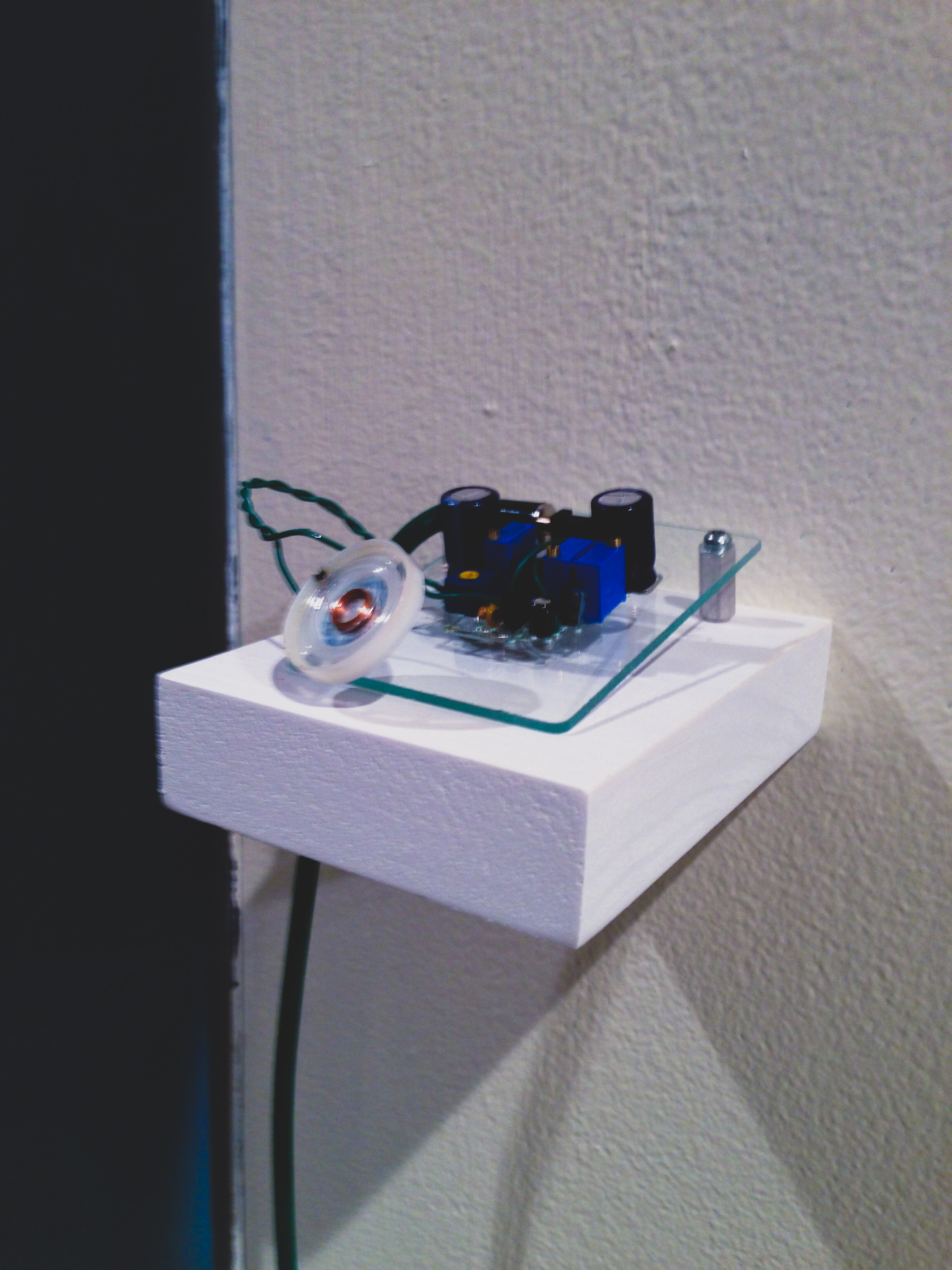

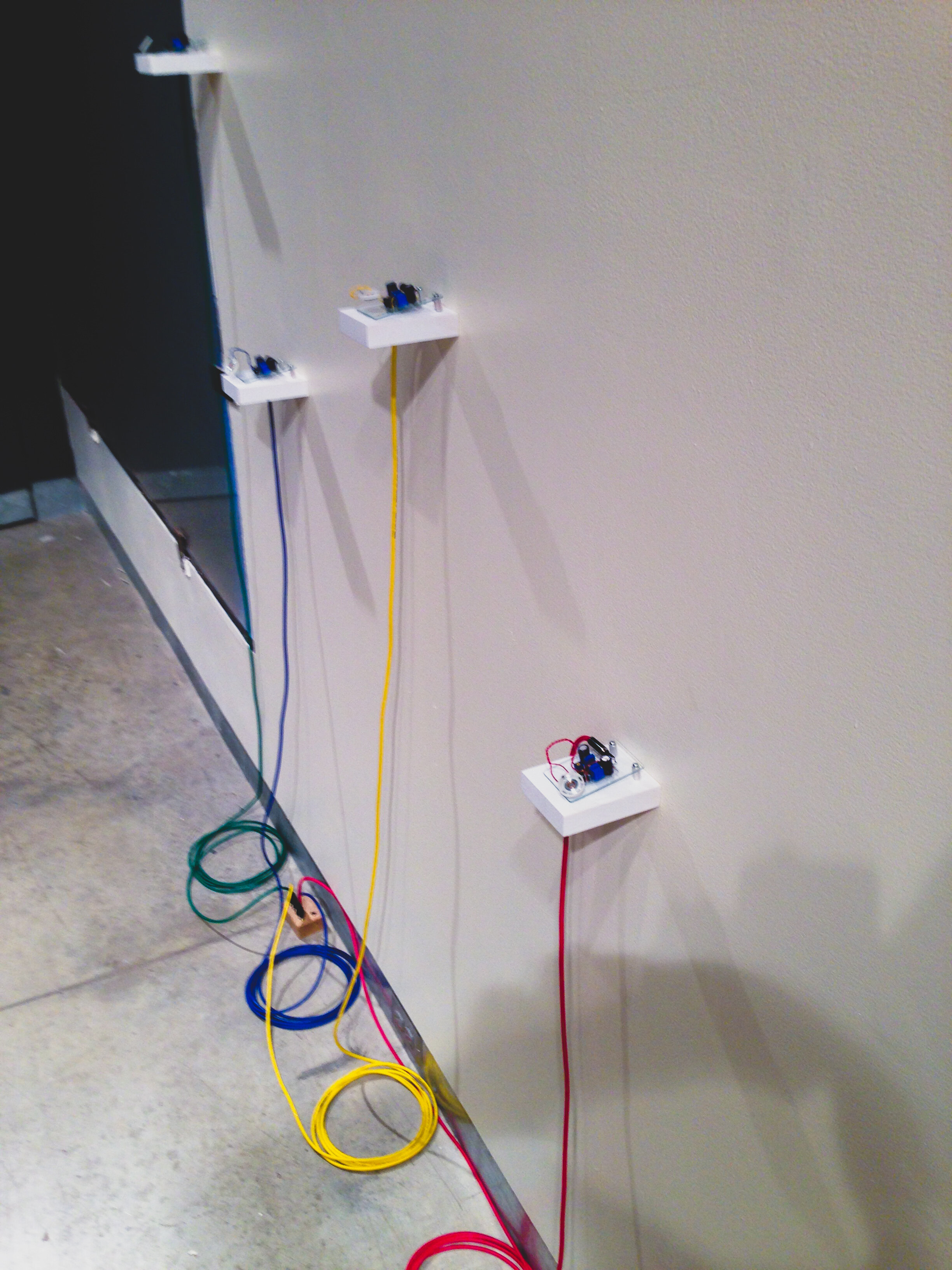

untitled (glass birds)

untitled (glass birds)

electronic circuits built on drilled glass

2014

This work was completed during the Idea Furnace Residency Project at the Pittsburgh Glass Center. In the residency, non-glass-based artists were invited to explore their work in the context of glass. My project involved milling tiny intricate holes in thin sheets (1/16”) of clear class to allow for the leads of through hole electronic components to be mounted on the glass surface and the circuits soldered together. We first tried cutting the profiles and milling the holes using a large flatbed cnc waterjet cutter. It was interesting to see a machine capable of cutting straight through 6” steel milling such delicate material. Unfortunately, the delicacy of the material and cuts were beyond the tolerance we could achieve in this process. After many failed attempts, I shifted my attempts to milling on a cnc machine with tiny diamond cutting tooling. It took some trial and error to figure out methods that could mill through the class with the needed precision, without breaking the glass, but eventually a method was developed. In the end, the process developed took about 9 hours of cutting time for each glass sheet (and some were lost, often after 75% complete!) It was interesting to me to struggle through the very laborious process of making one material do what another does so easily… The glass was a great substrate to accentuate the subtle visual elements of the electronic circuits.